Introduction

In the intricate, complex world of construction, the seamless integration of Mechanical, Electrical, and Plumbing (MEP) systems is critical to a modern building’s functionality, safety, and efficiency. However, translating engineering designs into precise on-site installations which are functional and efficient is no small feat. This is where MEP Shop Drawings come into play.

Serving as the intermediary between conceptual design and physical execution, these detailed technical drawings ensure that every duct, conduit, pipe, and cable is installed accurately, efficiently, and in compliance with project specifications. Without them, the construction process risks delays, cost overruns, and operational inefficiencies. This article explores how MEP shop drawings act as the linchpin of successful construction projects, bridging gaps in communication, resolving conflicts, and enable flawless executions.

What are MEP Shop Drawings?

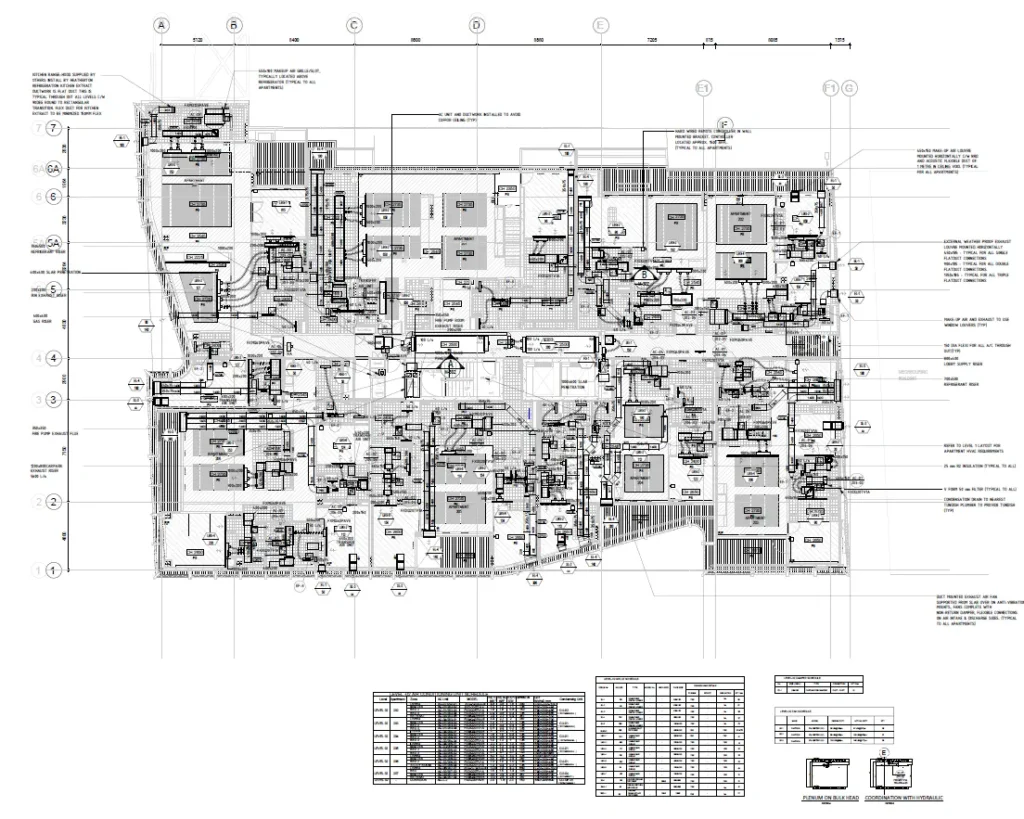

MEP shop drawings are specialized, detailed and dimensionally accurate diagrams created by contractors, subcontractors, fabricators, or specialized drafting teams based on the design drawings issued by consultants. Unlike design drawings, which focus on the ‘what’ and ‘where’ of a system, shop drawings dive into the ‘how.’

They provide step-by-step guidance for manufacturing components, assembling systems, and installing equipment. These drawings include precise measurements, material specifications, installation sequences, and coordination details tailored to the unique requirements of a project.

The key components of MEP shop drawings include:

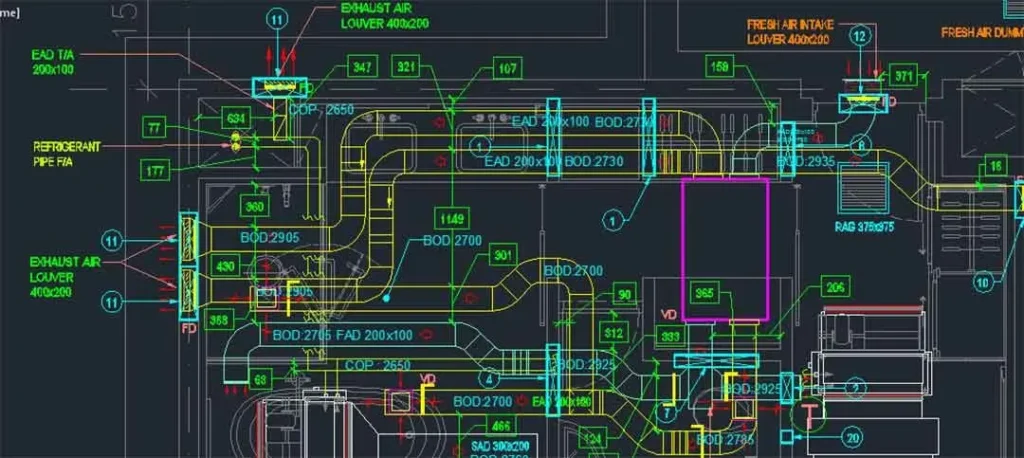

- Mechanical Systems: HVAC layouts, ductwork routing, equipment placement, and insulation details.

- Electrical Systems: Power distribution plans, lighting circuits, cable tray routing, and panel schedules.

- Plumbing Systems: Pipe sizing, valve locations, drainage slopes, and fixture connections.

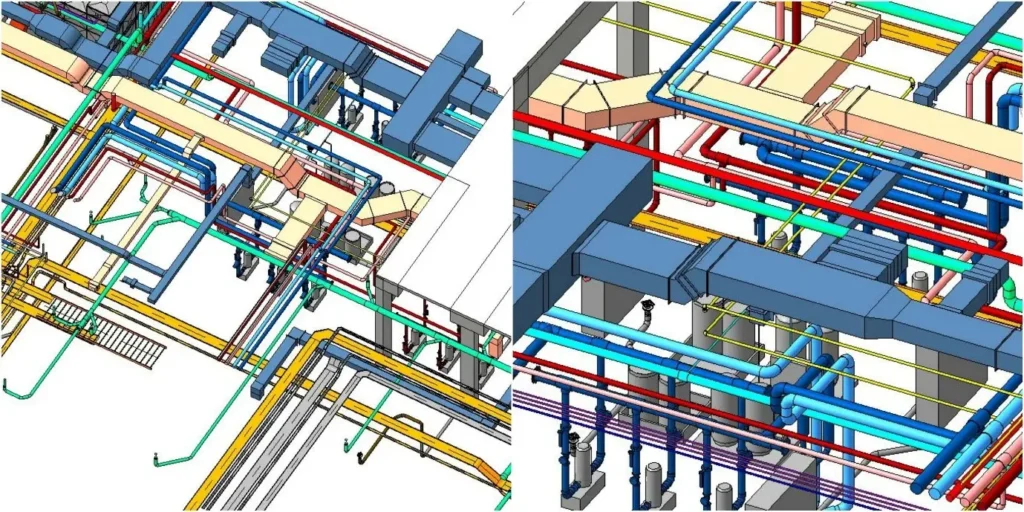

These drawings are typically prepared using Building Information Modeling (BIM) software such as Revit or AutoCAD MEP, which facilities coordination among various trades. By translating abstract design concepts into actional instructions, shop drawings serve as the common language for architects, engineers, contractors, and installers.

Role of shop drawings in bridging the Design-Installation Divide

Enhancing Design Intent through Precision

The design stage often focuses on the macro view – space planning, system layout, and compliance with codes. However, real world site conditions may vary, and a purely theoretical and aesthetic design might not be directly feasible. Shop drawings interpret these gaps in design and add layers of details – such as exact clearances, support structures, and connection methods. This occurs in a manner that considers the constructability, field constraints, and trade-specific requirements.

For example, a design might place HVAC ducts and electrical conduits in the same ceiling cavity without considering space limitations. Shop drawings for these elements into real spatial relationships, identifying potential clashes early in the process and enabling resolution before materials are fabricated or installed.

Facilitating Coordination between Trades

One of the most significant advantages of MEP shop drawings is their role in interdisciplinary coordination. MEP systems are deeply intertwined and must coexist with architectural finished and structural components. Electrical conduits share spaces with plumbing pipes, while HVAC ducts must avoid fire suppression systems. Shop drawings provide a platform for all stakeholders to visualize overlaps and conflicts, allowing for resolution through coordination meetings or clash detection software.

Coordination drawings – often a part of the MEP shop drawings package – highlight the spatial relationships among different systems. Contractors can identify conflicts in advance – such as a pipe intersecting a duct – and revise layouts before breaking ground – ensuring efficient use of space and avoiding costly rework during installation.

A study by the Dodge Data & Analytics (2020) found that nearly one-third of rework in commercial construction stems from clashes between MEP systems and other building components. Detailed shop drawings, combined with BIM-based clash detection, can reduce these conflicts by up to 9%.

Enabling Accurate Fabrication & Prefabrication

Detailed MEP shop drawings are essential for off-site location. Ductwork, piping, and electrical panels are often prefabricated to reduce on-site labor, improve quality control, and accelerate project timelines. However, prefabrication demands a high degree of accuracy, and this can only be achieved with precise, coordinated shop drawings.

By specifying exact quantities, material grades, orientations, fabrication techniques, and connection points, shop drawings enable contractors to order pre-assembled components – like prefabricated duct sections or modular plumbing racks – that shall fit seamlessly into the building. This reduces on-site labor, accelerates timelines, and improves quality control – minimizing the potential for human error. Research by FMI Corporation, 2022, revealed that projects using shop drawings to prefabricate MEP components off-site cut labor hours by up to 40%, while improving quality and safety.

Ensuring Compliance with Codes & Standards

Many regulatory authorities and project consultants require the submission of MEP shop drawings for review and approval before installation begins – local building codes, safety regulations, and industry standards like ASHRAE, NEC, and IPC dictate how MEP systems must be installed. These drawings are checked for code compliance, design conformity, and integration with other systems.

This proactive approach reduces the risk of non-compliance penalties and post installation modifications – alongside increasing the speed of approvals. Moreover, having approved shop drawings provide legal and contractual assurance to contractors. They act as a benchmark for verifying the scope of work and defending claims in case of disputes.

Improving Communication among Stakeholders

Construction projects involve numerous stakeholders – owners, architects, engineers, contractors, and subcontractors. MEP shop drawings serve as a universal reference point, enhancing communication across teams. By presenting all necessary installation details in a standardized format, they help avoid misunderstandings, scope gaps, and misaligned expectations. Clear documentation fosters smoother workflows and contributes to better decision-making, especially when unexpected site conditions require quick adjustments.

Detailed Shop Drawings Prevent On-Site Errors

Even minor discrepancies in MEP installations can lead to significant operational issues. For example, an incorrectly sized pipe may reduce water pressure, while misaligned electrical conduits could pose fire hazards. Once shop drawings are approved, they serve as a definitive guide for site teams. Detailed shop drawings mitigate such risks by:

- Clarifying Ambiguities: Design documents may use generic symbols or notes – for example, ‘install conduit as per code.’

- Shop drawings replace ambiguity with specifics, such as conduit sizes, bend radii, and junction box locations.

- Sequencing Installation Steps: Complex installations require a logical order of operations. Shop drawings outline workflows, such as installing main ducts before branch lines or laying underground plumbing before pouring concrete slabs.

- Enabling Quality Assurance: Contractors use shop drawings as checklists during inspections, verifying that installations match approved plans.

Installer rely on these drawings to understand routing, elevation levels, anchoring methods, and clearance requirements. The clarity of information within these documents directly impacts the quality and speed of installations.

Case in Point: Real World Impact

Consider a high-rise commercial project where the design team envisioned a centralized HVAC system. The initial plans showed air handlers on the roof and duct shafts running vertically. However, the shop drawings revealed that the shafts conflicted with the elevator mechanical rooms. By rerouting ducts early in the process, the team avoided costly demolition and delays. Similarly, in a hospital project, electrical shop drawings ensured that critical circuits for life-saving equipment were clearly marked, isolated, and compliant with redundancy standards.

The Role of Technology

Modern drafting tools like Building Information Modeling have revolutionized the way shop drawings are created. These tools enable 3D visualization, automated clash detection, data analytics, and real-time updates. BIM has become a cornerstone of MEP coordination, allowing designers and contractors to simulate installation sequences, monitor spatial constraints, and identify conflicts before they occur.

Cloud-based platforms further enhance transparency, allow for collaborative review and markup of shop drawings – speeding up the approval process and ensuring version control without geographical boundaries. These technological advancements make MEP shop drawings not just a set of technical documents, but a dynamic component of the overall construction management process.

At The End

MEP shop drawings are the unsung heroes of construction projects, transforming abstract designs into tangible, functional systems. These are far more than technical illustrations – they are the linchpin that holds together the design and installation phases of a construction project. By fostering collaboration, eliminating conflicts, and ensuring precision, they bridge the critical gap between design intent and on-site execution.

By transforming conceptual designs into executable, clash-free, and code-compliant plans, these drawings ensure precision, reduce risks, and facilitate smooth on-site execution. In an era where timelines are tight and margins are thinner, investing in detailed shop drawings is not just a best practice – it is a necessity.

As technology continues to advance, these documents will remain indispensable in delivering buildings that are safe, efficient, and built to last – they are not just a step in the process, they are the blueprint for turning vision into reality. Whether for a sprawling industrial facility or a compact residential complex, MEP shop drawings prove that success lies in the details – one accurately installed component at a time.

Frequently Asked Questions (FAQs)

These FAQs reinforce the critical role of MEP shop drawings in modern construction, addressing practical concerns and highlighting their value in delivering efficient, compliant, and conflict free installations.

How do shop drawings improve project timelines and budgets?

By resolving spatial conflicts, clarifying ambiguities, and enabling prefabrication, shop drawings minimize on-site rework and delays. For example, prefabricating ductwork or plumbing modules off-site reduces labor hours and accelerates installation. This precision also prevents costly errors, such as ordering incorrect materials or violating code requirements.

Are MEP shop drawings legally required for construction projects?

While regulations vary by region, most building authorities and project contracts mandate shop drawings for complex MEP systems. They serve as a contractual record of how installations will comply with design specifications, codes, and safety standards. Even in cases where they are not legally required, they are considered the best practice to ensure quality and accountability.

Who is responsible for creating MEP shop drawings?

Shop drawings are typically prepared by MEP contractors, subcontractors, or specialized fabrication firms. These stakeholders use the original design documents as a baseline and add technical details required for manufacturing and installation. The drawings are then reviewed and approved by the design team – architects or engineers – to ensure alignment with the project’s intent.

How has technology like BIM improved the shop drawing process?

Building Information Modeling (BIM) allows stakeholders to create 3D visualizations of MEP systems, enabling real-time clash detection, spatial coordination, and data integration. BIM-based shop drawings are more accurate, collaborative, and adaptable. For instance, changes to an electrical layout in the model automatically updates the related components – reducing manual revisions and errors.

Submit your project plans for a comprehensive MEP shop drawing review and discover how our expertise can eliminate installation risks. Contact us to get started.

Contact Us